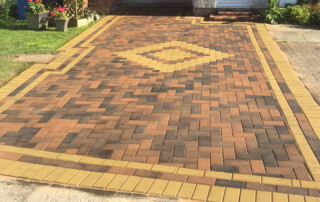

Eye-catching and always unique, block paving – aka brick weave – is an ideal surface for driveways, patios, parking areas, and garden paths.

GET YOUR FREE QUOTE!

Eye-catching and always unique, block paving – aka brick weave – is an ideal surface for driveways, patios, parking areas, and garden paths.

Block Paving – Cambridge

At SGR Surfacing Ltd, we create block-paving surfaces that transform driveways and patios in Cambridgeshire into works of art. This modern mosaic of soft, natural colours adds a unique charm to any property – and beyond the aesthetics, we guarantee sturdy foundations and effective drainage. Committed to turning your vision into reality, we’ll work closely with you throughout the project.

High visual impact

Individual block replacement

Variety of colours and styles

Good drainage

Hard wearing

Survey

Excavation

Sub base

Edging

Block laying

Driveways

Paths

Patios

Open spaces

Garden design

The Process

Attention to detail at every stage of the process is vital if we’re to get it just right. These are the six steps involved in creating a superb block-paving surface.

1

Free site survey – Preparation is of the utmost importance to us. At the planning stage, we’ll take measurements, mark out the area, carry out risk assessments, and evaluate drainage options. Led by your requirements, we’ll decide on block sizes, colours, and finishes. To help you make these decisions, we can show you samples.

2

Excavation – Having scanned the site for utility conduits, we’ll dig the foundations. The excavated plot will be lined with a porous membrane, which will act as a barrier to our Type-1 sub-base, preventing it from mixing with the underlying soil. All the groundwork is done by the SGR team, as we prefer to maintain control and continuity.

3

Sub-base – The type of sub-base we use will depend partly on the chosen surface finish and drainage requirements. Typically, however, we’ll use MOT Type-1 hardcore or crushed concrete. The sub-base is well crushed to combat the risk of sinking, and we’ll lay it at a minimum depth of 100mm.

4

Kerbs and edging – Although it’s not essential to have one, a kerb acts as a retainer. Edging, on the other hand, is purely for decoration, and there are some lovely effects to be had by adding an elegant border. There’s a lot of choice when it comes to edging designs, so we’ll find one that matches your desired finish.h.

5

Drainage and manholes – Drainage is a vital part of the process. We only use linear drains made of stainless steel, because the metal is hard-wearing and crack resistant – and it doesn’t rust. If there are any manhole covers on the site, we’ll replace them with well-fitting recess manhole covers, which won’t spoil the aesthetics of the brick-weave surface.

6

Block laying – First of all, we’ll apply a layer of very finely crushed stone called screenings – or stone dust. We then lay down the blocks in your chosen pattern and carry out the necessary cuts. The blocks are fully compacted for a secure, level finish. To prevent the blocks from moving, we use a kiln-dried red sand for jointing.

Additional Care

For long-lasting protection, we can seal the block pave with a high-quality sealer, which will discourage weed growth and reduce the risk of discolouration. This service is not included in our standard quotes, but is available at an additional cost.

Block Paving Gallery

Get a free no obligation quote